Menu

Digging Condition Optimization

Precision Drilling & Blasting

- Revolutionizing drill & blast optimization through integrating open data platform and advanced analytics

Challenges

- High Variability in Digging Conditions

- - Drill & Blast design formulas do not consider local geology

- - Current manual data is subjective, inconsistent, and periodic

- - Over and under-blasting conditions:

- • Excess explosive usage,

- • Excess drilling,

- • Slow shovel productivity,

- • Added machine maintenance.

Solution

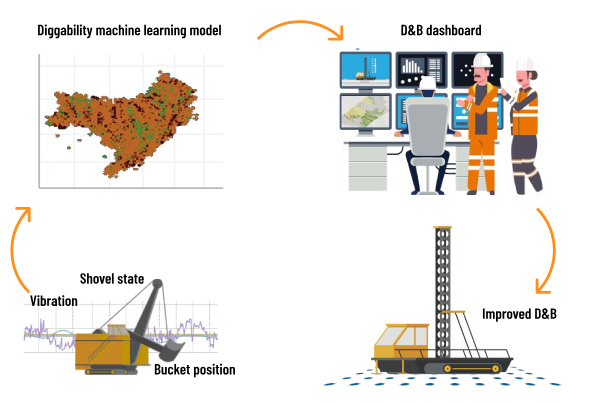

- Empower drill and blast engineers with actionable insights into the diggability of previously blasted regions by assessing the hardness of the blasted rock face during excavation activities performed by earth-moving vehicles. Our solution provides:

- • Comprehensive analysis of digging conditions.

- • Generation of a 'Digability Map' from vibration data collected during excavation.

- • Transmission of collected data to our cloud platform for further analysis.

- By correlating blast parameters with outcomes such as diggability and shovel productivity, engineers are equipped to optimize design parameters for subsequent blasts, provided the geological conditions remain consistent.

Benefits

-

Less Drilling:

Diggability Optimization improves hole pattern design/spacing and reduces unnecessary drilling and the resulting over-blasting. -

Optimized Powder Factor:

Blast engineers use diggablity index to optimize powder factor to achieve a consistent medium digging condition, avoiding over-blasted (soft) and under-blasted (hard) digging areas while reducing explosive usage/cost. -

Higher Loading Rate:

Better diggability allows shovels/loaders buckets to move in the face faster with more consistency, enabling faster dig-rates and improved performance of shovels/loaders. This means faster truck turn around time at loading location and reduces the overall cycle time of the operation. -

Less Equipment Damage:

Avoiding hard digging conditions, prevents damage events on shovels including lost tooth/adapter/ shroud, boom-jacking/stall, etc. The more consistent digging condition contributes to more uniform and therefore predictable wear on shovels. -

Better Fill Factor:

By optimizing blasting, mine achieves optimal fill factor on buckets and on trucks.

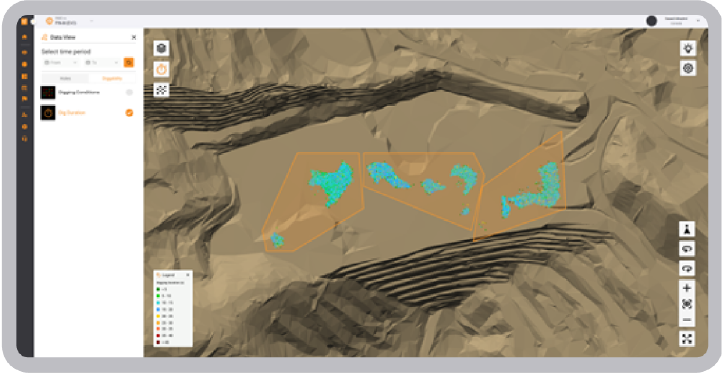

Digging Condition Optimization Dashboard

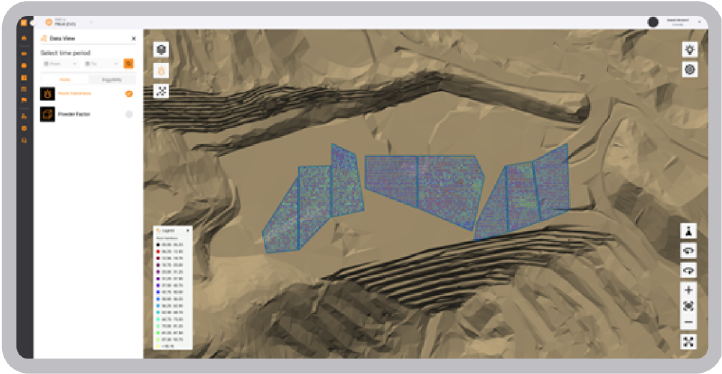

Rock Hardness

Rock hardness is taken from earlier drilling operations, part of Measurement While Drilling (MWD), and is interpolated for target polygon.

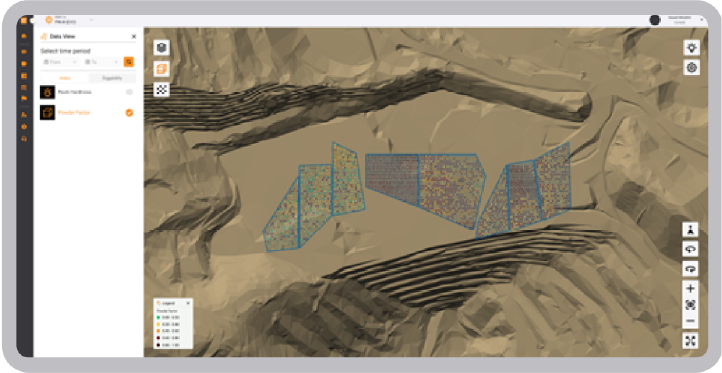

Powder Factor

Drill and Blast Engineers have used the Rock Hardness, type of ore and other parameters to determine how much explosive is required in the blast holes.

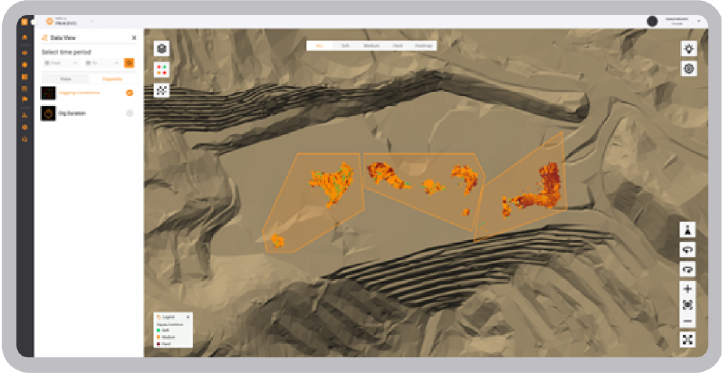

Diggability

As soon as shovel hits the ground, RIGID solution will output real-time Digging Condition Index for every bucket at exact bucket locations. The information is available as point cloud or heatmap to be analyzed.

Shovel Productivity

Shovel Productivity such as dig duration is also sent in real-time alongside Digging Condition Index. Together, this post-blast real-time feedback enables optimizing next blasts to avoid under/over blasting.

Testimonial

RIGIDprecision has become an indispensable part of our daily operations, consistently delivering valuable insights that enhances our productivity and efficiency.

Sr. Project Manager - Mining

Machine Support

Remotely managed with RIGIDportal™

- All of our systems can be monitored, maintained, and managed remotely via RIGIDportal web interface.

Case Study: Optimization of Drill & Blast