Menu

Shovel Maintenance Optimization

Precision Digging & Loading

- Accurate location of shovel and excavators bucket on real-time basis

- Allow integrated geo-spatial data analysis for drill & blast optimization, orebody visualization and mine plan compliance.

Challenges

- • Unplanned maintenance affects production.

- • Operator behaviour can cause excessive wear, premature failure and unwanted downtime.

Solution

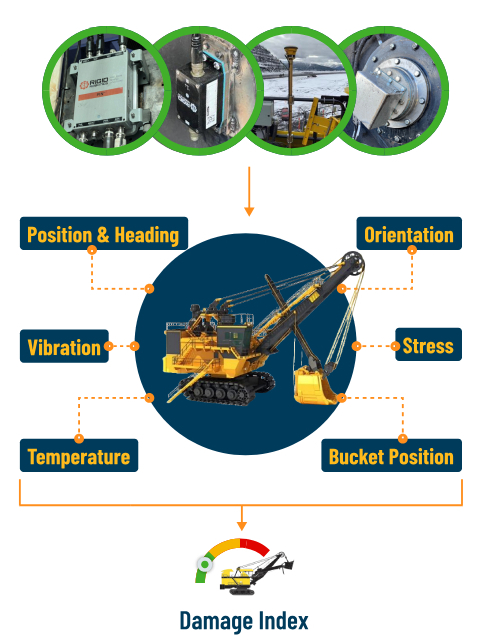

- Shovel Maintenance Optimization tracks Damage Index base on:

- • Vibration at strategic location

- • Digging Conditions of the shove

- • Major events such as Boom Jacking and Swing Impacts

Benefits

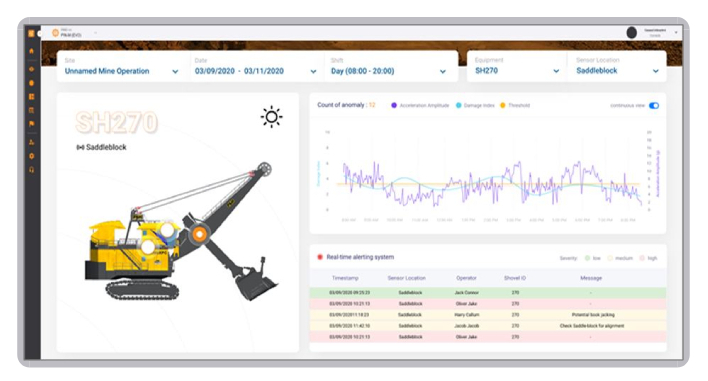

- • Dashboard for maintenance to view, analyze, get customized report

- • Anomaly detection on all of the above using AI

- • Real-time “Cumulative Damage Index” that can be used to plan maintenance events as opposed to fixed time interval.

Machine Support

Remotely managed with RIGIDportal™

- All of our systems can be monitored, maintained, and managed remotely via RIGIDportal web interface.

Case Study: Bucket Sensing

Bucket Telemetry

Objectives

- Accurate location of shovel and excavators bucket on real-time basis

- Allow integrated geo-spatial data analysis for drill & blast optimization, orebody visualization and mine plan compliance.

Solution: RIGIDprecision™ + HPShovel + HPBucket addons

- Scalable real-time data from shovel enabled by RIGIDsense™ hardware

- Advanced bucket-sensing algorithm to determine the accurate location of bucket on a real-time basis.

- Multiple data pipelines for different applications such as payload monitoring, drill & blast optimization, ore sorting, and coal seam visualization

Impact

- Bucket position with less than 20 cm accuracy

- Enabled increase in mine plan compliance, drill and blast optimization and improved recovery

Dig-to-Limit Application

Objectives

- Improve shovel and excavator spatial awareness

- Improve operators’ ability to remove material as per the mine plan

- Reduce personnel exposure to hazardous environment

Solution: RIGIDprecision™ + HPShovel + HPBucket addons

- Scalable real-time data from shovel enabled by RIGIDsense™ hardware

- Dig-to-limit real-time guidance to operators enabled by DIG.D2L application

- Detailed engineering analysis and plan refinements using historical data

Impact

- 5-10% increase in mine plan compliance

- Improved recovery

- Reduction in surveying requirements

- Improved machine productivity and reduced operating cost